- Joined

- Apr 13, 2013

- Messages

- 2,449

- Reaction score

- 1,372

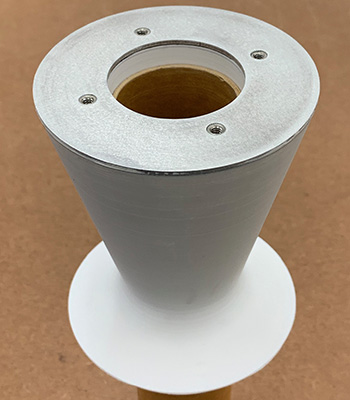

One issue for the aft CR is heating from the motor. I'm presuming this is due to base drag pulling hot gasses up, but am not certain. This may prevent the use of printed parts at the aft end of a rocket. More investigation is required.

After an AT J270W flight, the aft CR was blacked with soot and there was an irregular section melted. (It didn't go all the way through the 6mm thick ring, but it's certainly concerning.) This was printed in ABS, using the settings determined in my strength testing experiments.

The CRs (like the fins) were printed in red ABS. You can still see the color in the fins, but the aft end is almost obscured with soot.

After an AT J270W flight, the aft CR was blacked with soot and there was an irregular section melted. (It didn't go all the way through the 6mm thick ring, but it's certainly concerning.) This was printed in ABS, using the settings determined in my strength testing experiments.

The CRs (like the fins) were printed in red ABS. You can still see the color in the fins, but the aft end is almost obscured with soot.